Heat Exchanger Coil's Copper Tube Processing:

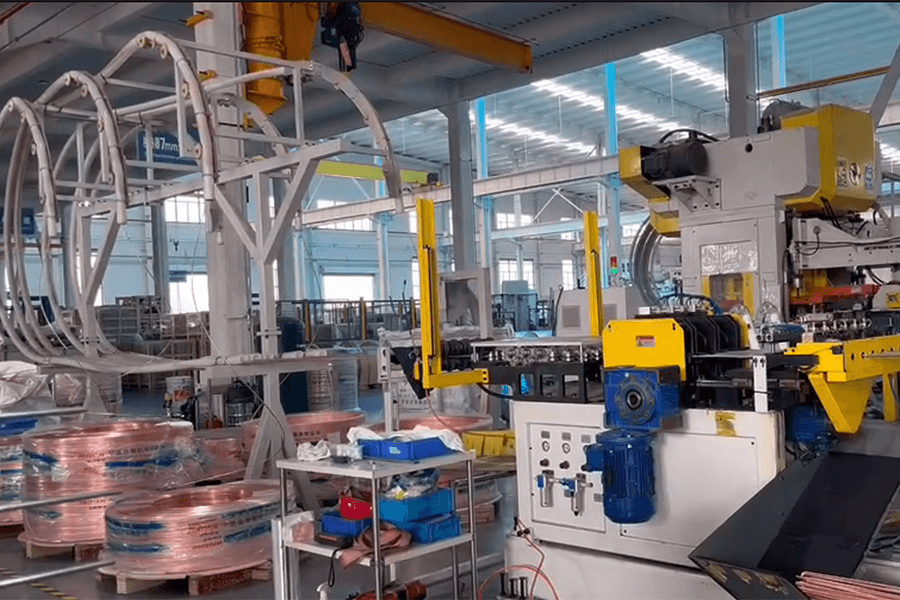

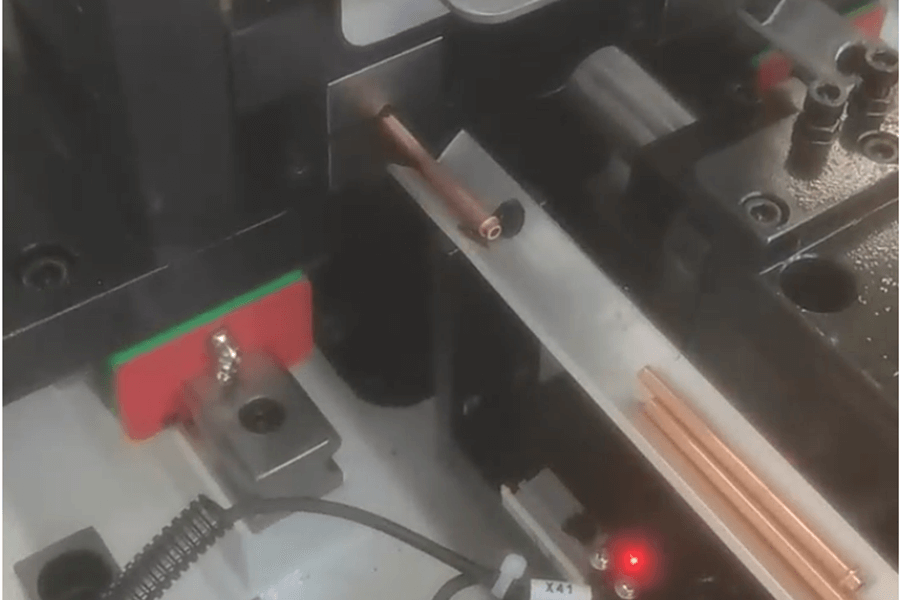

Copper Tube Loading

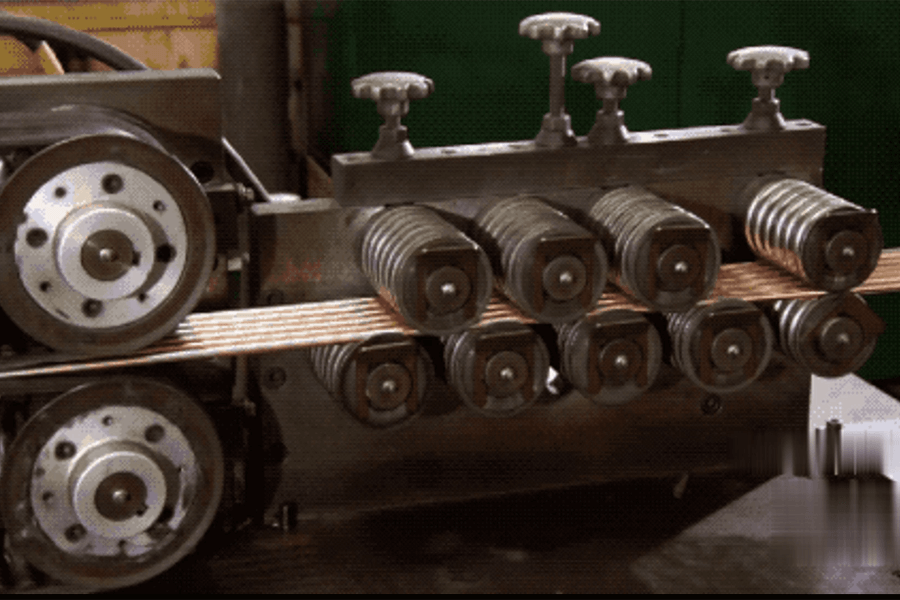

Straightening Curved Copper Tubes

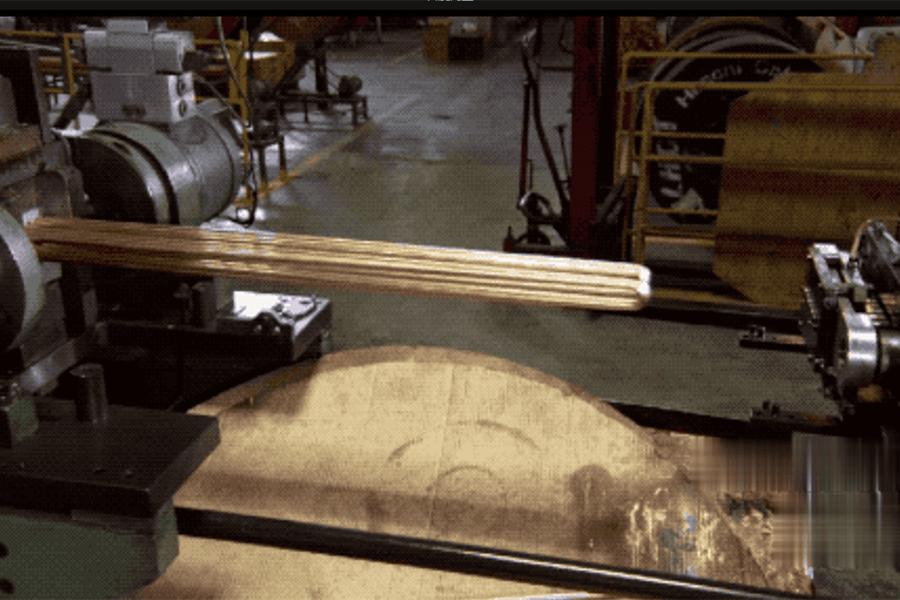

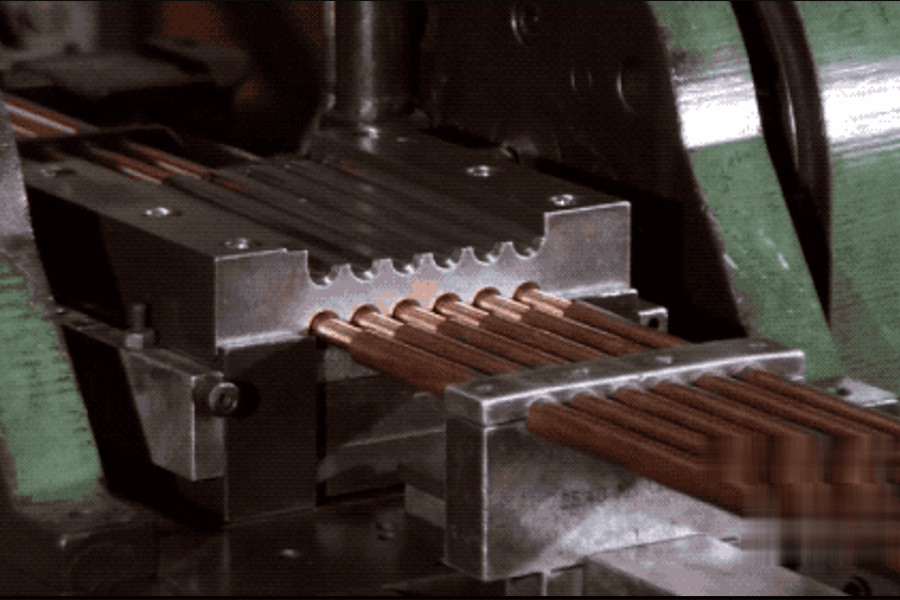

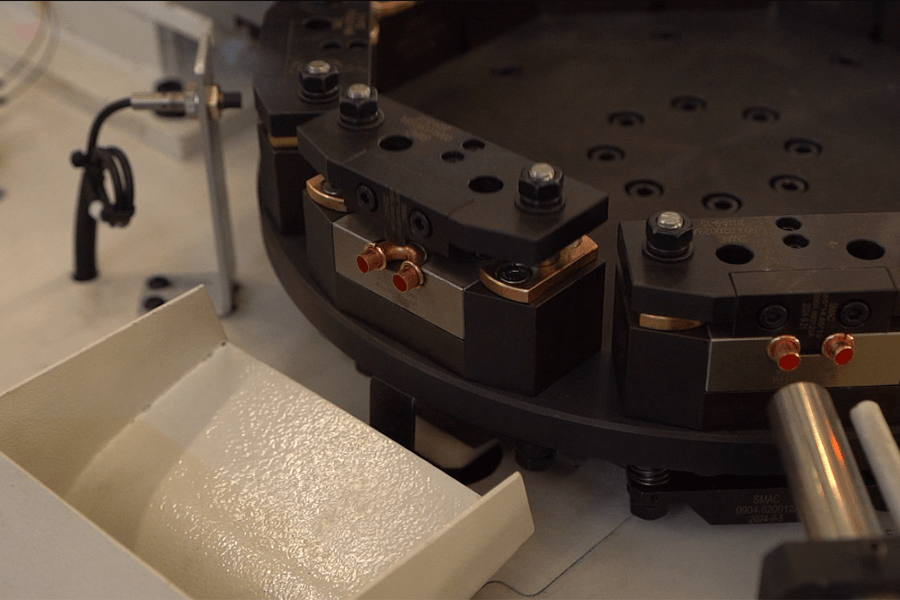

Bending the Tube: Bending Copper Tube into a Long U-Shaped Tube by Hairpin Bender

Tube straightening and cutting: to straighten and cut tube chiplessly by tube cutting machine cut tube to length

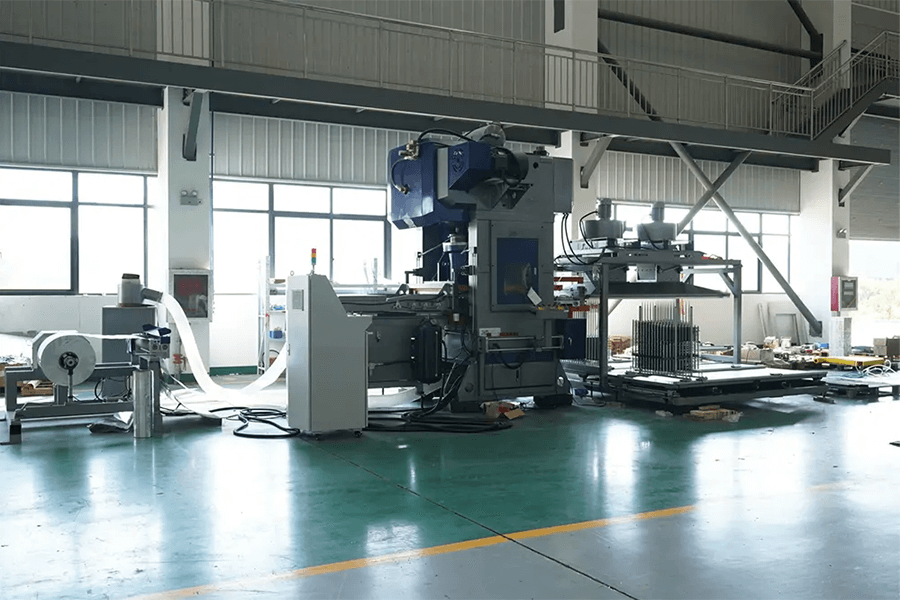

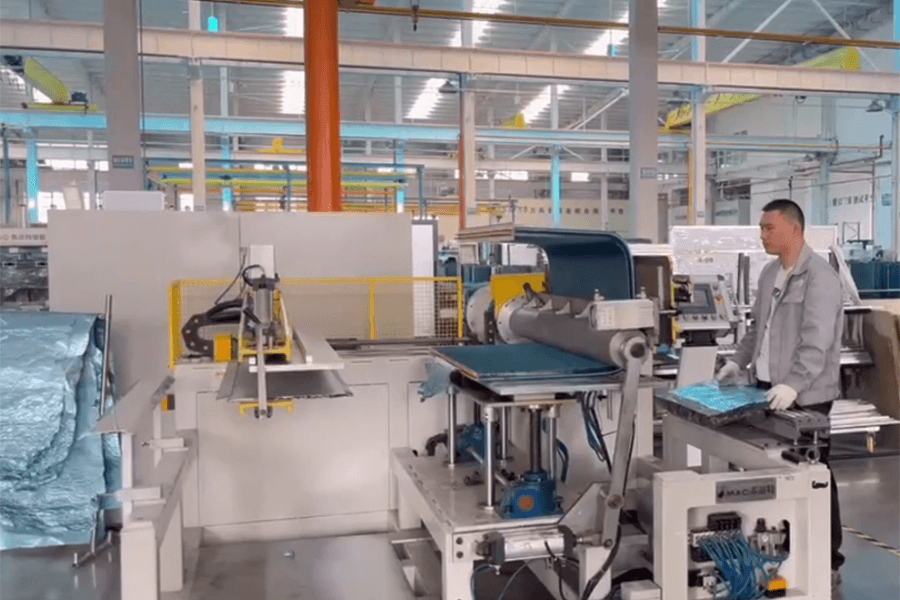

Heat Exchanger Coil's Aluminum Fin Processing:

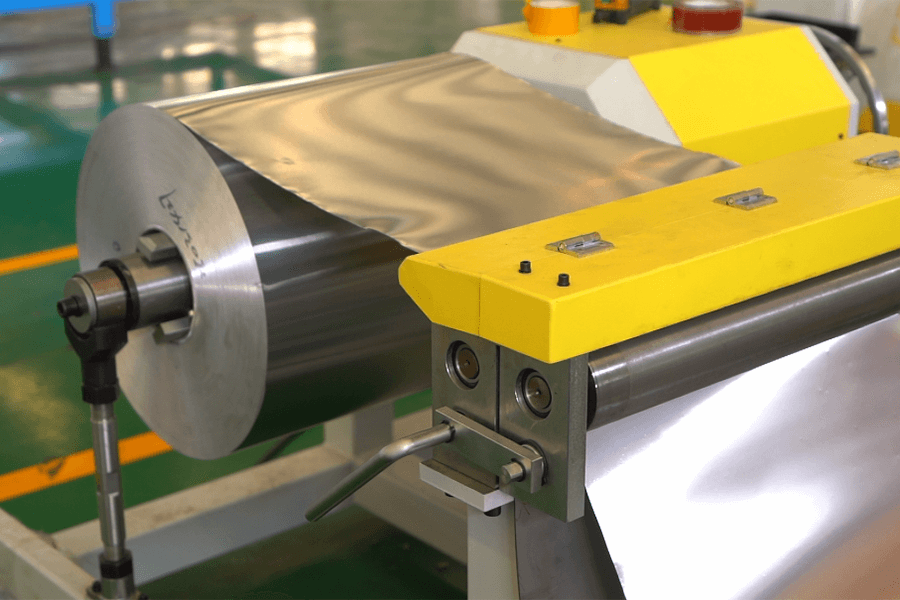

Aluminum Fin Loading

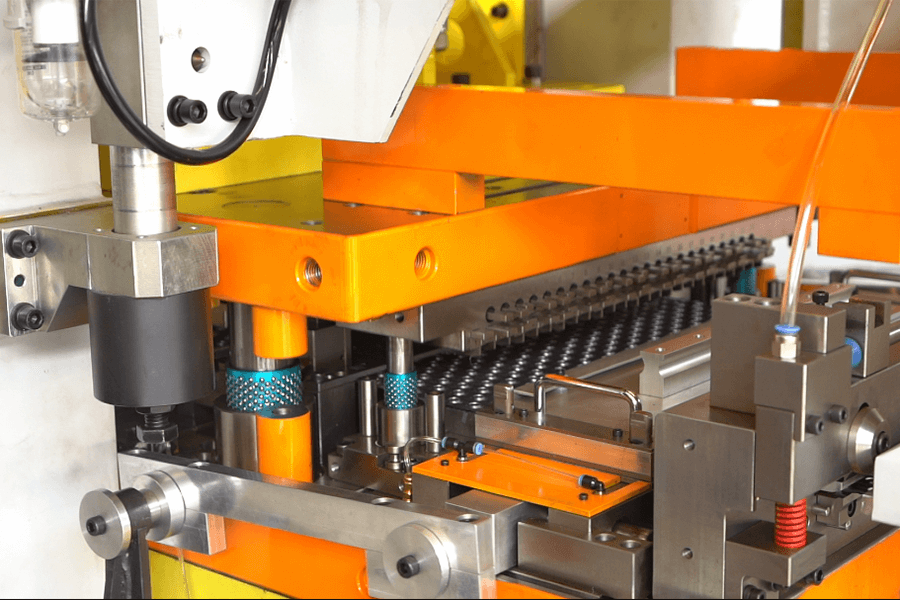

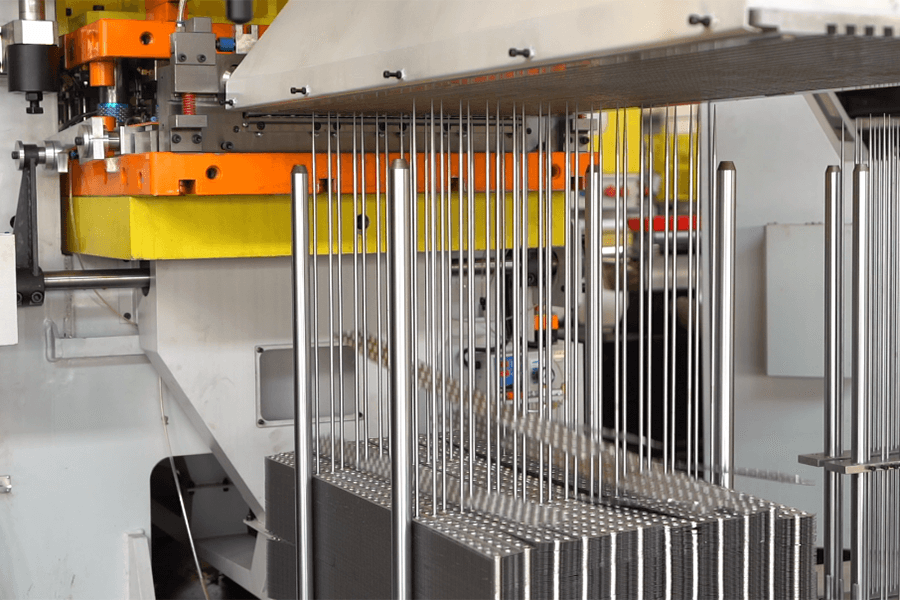

Stamping: The Fin Press Processes Aluminum Foil into Fin Designs by Fin Press Line

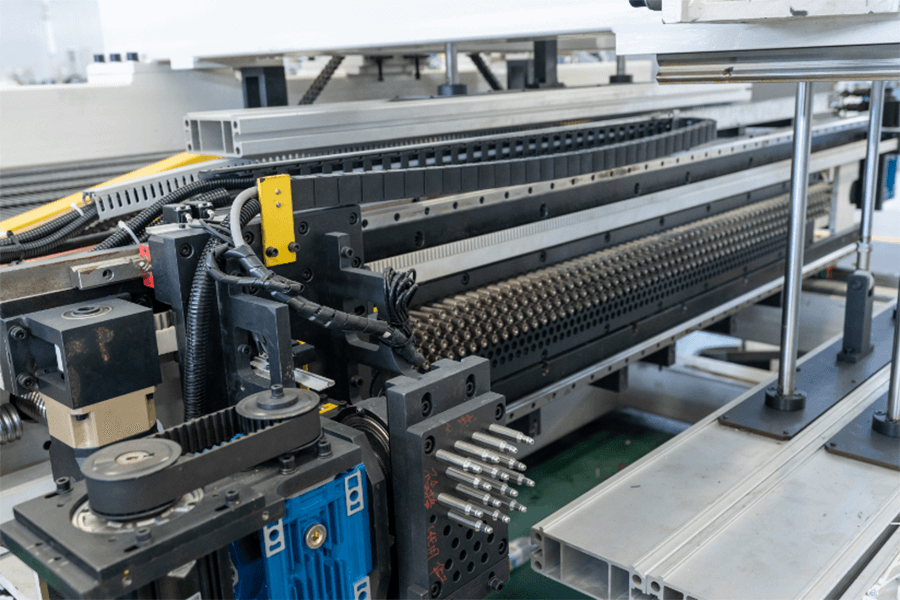

Inserting the Tube: Inserting the Long U-Shaped Heat Exchange Copper Tube into the Stacked Fins manually or automatically by using SMAC's automatic tube insertion line.

Expansion: Expanding the Copper Pipe and Fins Together to fit tightly,Completing the Formation of the Heat Exchanger Coil

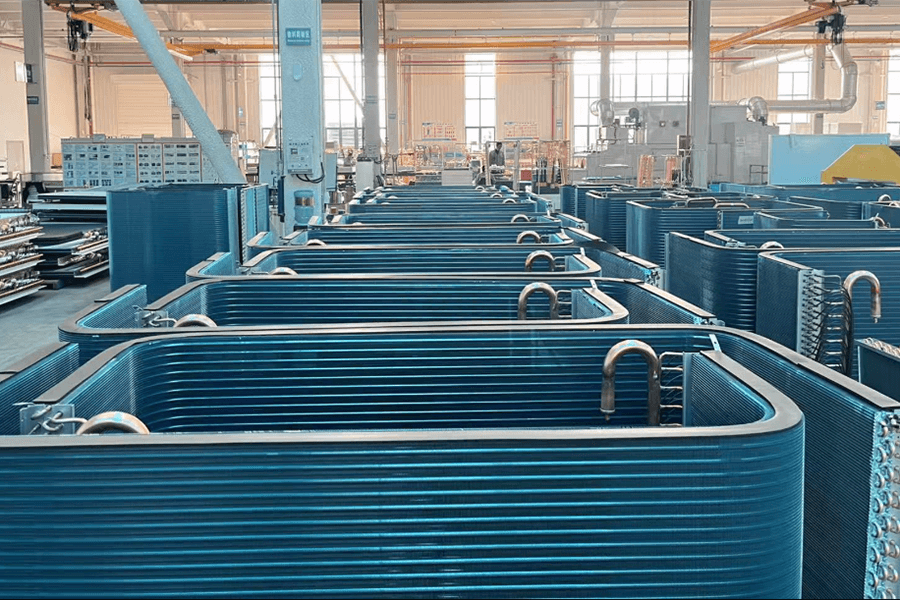

Bending: Bending the Heat Exchanger coil into L-Shaped or G-Shaped Configurations to Fit the Air Conditioning Housing by coil bender machine

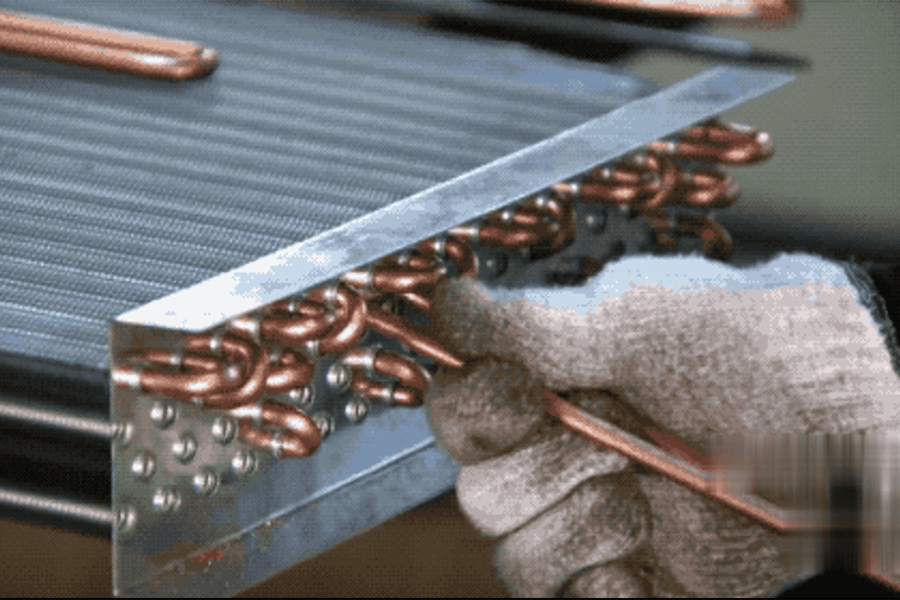

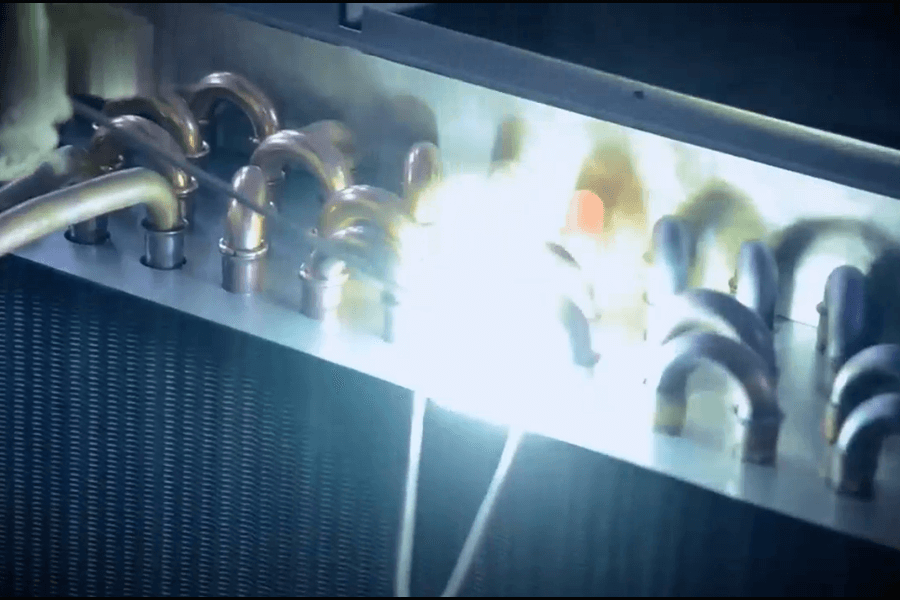

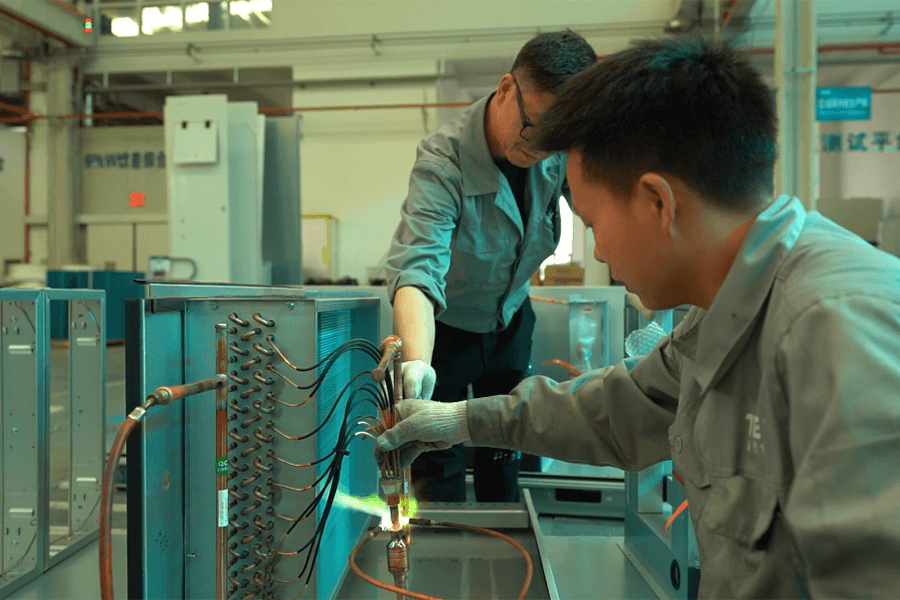

Welding: Welding the Small U-Bends made by Return BenderAccording to the Flow Path Design

Leak Testing: Filling the Welded Heat Exchanger with Helium Gas, Maintaining Pressure to Check for Leaks

Post time: Jul-25-2025