Advanced Quick Color Change System with Efficient Automatic Cleaning and High Airflow Technology

The powder is fully fluidized in the powder box of the powder supply bucket, and the

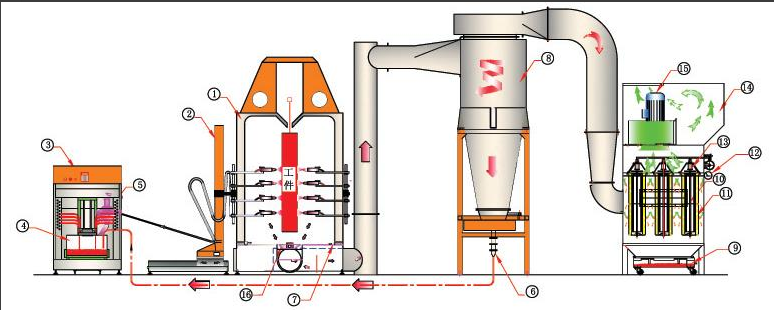

powder is transported by the powder pump through the powder tube to the spray gun. The powder is charged through the corona area of the spray gun electrode and adsorbed to the surface of the grounding workpiece. After filter air make the spray internal negative pressure, and the end of the adsorption powder with the airflow, the inner wall smooth pipe, suction to the big cyclone separation, particles are heavy powder, with the rotating air centrifugal force along the cyclone cylinder wall, the powder sieve to conical powder bucket, again by the extrusion valve recovery device to the powder bucket recycling. The powder with light particles flows through the secondary pipe with the extraction atmosphere. The powder is completely filtered by the filter element. The built-in rotary wing pulse blows from the inside and outside the filter element to beat the powder fall to the waste powder bucket, and keep itself clean, maintain effective ventilation strength.

| Powder types | Qualified for an organic powder coating |

| Suspension chain speed | According to customer needs |

| Transmission type | Underslung conveyer |

| Work piece rotation per minute | Not have |

| Workpiece temperature | <35℃ |

| Operating environment requirements | Relative humidity <75%, and surrounding temperature: <40℃ |

| Average coating thickness | According to customer needs |

| To be coated with workpieces | - |

| Recycling powder | 10 species |

| Number of powder color species | 10 species |

| "Automatic slot (including fixed slot) on each side" | Five |

| The velocity of the air flow nearby | <0.1 m/s |

| "Encore LT Manual work Spray gun once on a powder rate" | 70% (Aksu polyester thermosetting powder coating in flat test on board) |

| Manual operating table | 2 manual spray sites |

| Power supply standard | Three-phase five-wire system, 380 V, 50 Hz, Voltage fluctuation range of +/-10% |

| "Minimum compressed air is used for measure" | 5.56 square meters / min * 2 |

| Maximum compressed air is used for measure | 6.03 m³ / min * 2 |

| Maximum input pressure | 8 bar (8.0 Mpa) |

| Minimum input pressure | 6 bar (0.6 Mpa) |

| Compressed air contains the oil content, water quantity and particles | Pressure dew point -20℃ or water content 1.3g / m³, oil content 0.01 ppm, with dust amount 0.01 μm |

| The powder spraying equipment is grounded | "Use 3-5 root diameter 32 mm galvanized tube, length of about 3000 mm, driven into the ground down to earth" |

| Maximum electricity consumption | 60.0 KW |

| Floor / pit | "A. Surface bearing capacity: 5 tons / square meter; B. The flatness is required for every 1,000 mm in length, high and low error in the range <1.5 mm." |

| Cyclone separation rate | 97% (less than 3% of powder particle size below 10 um) |

| Equipment layout drawing and work art flow chart | See drawings for details |

| Else | Not have |

| Item Name | Item Details | Model | Description | Quantity | Unit |

| Spray gun carrier system | Elevator | YW2000 Digital Reciprocating Machine | (Reciprocating) Lifting machine with a load capacity of 50kg; (Synchronous Belt) structure, reciprocating operation, stable and durable | 2 | Set |

| Quick color changing and powder supply center system |

Color changing for powder center | Dust-free Powder Supply Center | Equipped with a 120kg powder hopper, equipped with a high-flow fluidizer, to provide qualified powder for the spray gun, and install 12 powder feeding pumps | 1 | Piece |

| Powder screen | Efficient Vibrating Fluidized Bed | Independent vibrating fluidized bed, diameter 500mm, mesh 100 mesh. | 1 | Set | |

| Spray powder room | Pink room board and side board | Engineering Plastic Powder Wall Panels | The powder wall panels and the top are welded by 6mm and 12mm imported engineering plastics, and the bottom is welded by 10mm engineering plastics, which is durable. | 1 | Set |

| Recovery system | Cyclone Components | Primary Large Air Separator | The large air separation dust recovery system adopts the principle of centrifugal separation. The powder in the booth is recovered by the air pump to the large air separator, which automatically separates the ultrafine powder in the powder and air mixture. The separation rate of the large air separator is ≥97%. | 1 | Set |

| Secondary post filtration system | Membrane Filter Element | The Dongli membrane filter element has innovative design and the best performance, which can increase the effective filtration area, improve the self-cleaning ability and reduce the system resistance. The filter element is used as the key component of the powder recovery and filtration device. | 24 | Set | |

| High-Efficiency Energy-Saving Fan, South Ventilator, South Fan | 30.0KVA motor and South Ventilator fan blade (air suction volume 20000Nm³/h). | 1 | Set | ||

| Secondary Post-Filtration System Powder Recovery Tank Body | This tank body is used for powder recovery, easy to clean. The bottom has a movable waste powder collection box, and the top of the tank body has a 杠杆 control main power switch for the opening and closing of the main power supply. | 1 | Set | ||

| Electrical system | Central control spraying system of the powder room | Rack-Mounted Vertical PLC | Control the opening and closing of the main power supply, control the start and stop of the spray booth, control the spray gun cleaning system, control the lifting machine, etc. All operations of the equipment can be completed through the touch screen. | 1 | Set |

| Powder room lighting | 600LU | 600LU illumination, dustproof, 6 groups in the booth, 2 groups on the manual opening side. | 6 | Group | |

| Core parts warranty | Booth Internal Standard Configuration | The whole booth system is guaranteed for one year (excluding wearing parts). | 1 | Batch |

| Item Name | Brand | Position |

| Programmable Logic Controller | Siemens (Germany) | S7-200 |

| Human-Machine Interface | Siemens (Germany) | KTP 600DP |

| Cam Switch | Moeller (Germany) | P3-100 |

| Circuit Breaker | Schneider (France) | C120H, OSMC32 |

| AC Contactor | Schneider (France) | LC-D, LC-E |

| Buttons and Indicator Lights | Schneider (France) | ZB2, XB2 |

| Thermal Relay | Schneider (France) | LRD, LRE |

| Photoelectric Encoder | Omron (Japan) | E6B2-CWZ6C |

| Fluidization Plate | Tokyo (Japan) | Fluidization Bucket |

| Limit Switch | NAIS (Japan) | AZ7311 |

| Proximity Switch | SICK (Germany) | IME12-04NNSZW2S |

| Solenoid Valve | AIRTAC (Taiwan) | Spray Booth Cleaning Air Knife |

| Lifter Digital Inverter | Mitsubishi (Japan) | FR-D700 |

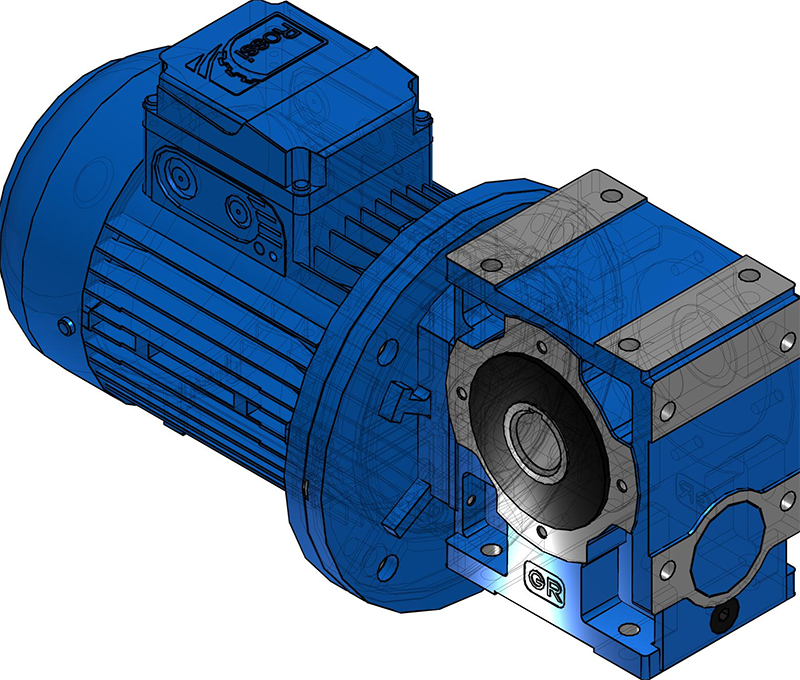

| Lifter Gearbox | TRANSTECNO (Italy) | Lifting Lifter |

| Lifter Motor | Siemens (Germany) | Siemens (Germany) |

| PTFE Nano-Coated Membrane Filter Element | Toray (Japan) | Filter |

| Exhaust Fan | Nanfang Fan | Filter |

| Sandwich PP Engineering Plastic Plate | New Helmer or Klinger (Germany) | Spray Booth |

| Vibrating Fluidized Bed | Tuzhong | 80 Mesh Screen Available |

| Item Name | Item Details | Description | Quantity | Unit | Picture | |

| Recovery system | Cyclonic system | Primary (Large Single) Cyclone Separator | Diameter: 1400mm Height: 5350mm The large cyclone separator adopts the principle of centrifugal separation. The powder recovered by the filter is sucked into the large cyclone separator, which automatically separates the ultrafine powder from the powder-air mixture. |

1 | Set | |

| Openable Cleaning Air Duct | In order to ensure color change, the bottom of the spray booth, the air inlet, and the connecting pipes of the spray booth are reasonably designed with doors that are easy to check and clean, so as to facilitate daily cleaning and internal inspection. | 1 | Set | |||

| Post recycling system | Toray Membrane Filter Cartridge (Japan) | Using high-tech membrane coating materials (PTFE), the service life of the filter cartridge can reach more than 5 years. It can filter ultrafine powder of 0.1-0.3 microns. Exhaust gas is directly discharged indoors. The filter cartridge is made of special technology, easy to clean, and has a long service life. | 24 | Pieces | ||

| Post-Filter Recovery Components | This component has a waste powder collection bucket. The filter cartridge uses a pleated filter material to separate the air, so that the powder recovery rate is ≥99.9%. The filter cartridge is cleaned by compressed air backflushing and detected by the filter differential pressure transmitter system. | 1 | Set | |||

| High-Efficiency Energy-Saving Fan and South Ventilator Impeller | It is a key component of the secondary post-filter recovery device. The motor power is 30KW, and the air volume is 20000Nm³/h; with high-density noise reduction device. | 1 | Set | |||

| Features: No backflow or siphon phenomenon; Pneumatic lifting device; Cone bucket design for easy collection of powder; Quick connect powder transfer dedicated interface; Combined with automatic powder return tube blowback, the single cylinder is easier to clean; Streamlined and enclosed pipeline system; The return air duct provides better durability, good grounding, and improves the safety of the cleaning process; Install a cleaning door at the connection point in the powder spraying room, and the operator can directly open the door to clean the interior when changing colors. The simple and fast implementation of changing from dark to light colors is' as long as it can be seen, it can be cleaned thoroughly '. |

||||||

| Item Name | Function | Description | Quantity | Unit | Picture | |

| Quick color change and powder supply center system | Powder Supply Center | Recovery Powder Center | Connected by the large cyclone recovery system; the quick-change center operation, with the function of fast mode and slow mode, combines the flexibility and simplicity of operation; processes the powder from the original powder or the new powder device, an integrated automatic fluidization device. Integrates electrical control, monitors the position through the level detector, the level detector controls the rise and fall of the powder feeding device, and the powder feeding device is equipped with a full internal return pump and fluidizing gas. The suction pipe, powder pump, pipe and spray gun can be automatically cleaned. The recovered powder is directly sent to the powder supply tank, and the large cyclone integrated automatic cleaning device. | 1 | Set | |

| Powder Barrel | Plastic Square Barrel | The plastic square barrel fluidized powder barrel is equipped with a high-flow fluidizer, which can better fluidize the powder in the powder barrel and convey qualified powder to the spray gun. | 2 | Pieces | ||

| Design Features | Usually regarded as the core part of automated production; Quick detachable integrated electric powder sieve (250 μ m pore size); The powder supply center is specially designed for quick color change, replacing the traditional powder supply bucket. The powder supply center is an integrated component in the rapid color change system, which affects the spraying quality of the final product. Place the powder box provided by the powder supplier in the position of the fluidized powder bucket, and after use, return the powder box to the warehouse; |

|||||

| Design Principle | The typical operation method of the powder supply center is to place the powder supply box on the vibration table. According to the instructions of the powder level detector, all powder pump suction tubes are inserted into the powder, and the fluidization tube is used to fluidized the surrounding powder. The fluidized powder is pumped into the powder tube by the powder pump and sprayed out by the spray gun. The powder that has not been sprayed onto the workpiece falls onto the floor of the spraying room and is then sucked into the cyclone separator, becoming a mixture of air and powder. In the cyclone separator, the powder is separated and sent back to the powder supply center through a dense phase valve. To avoid pollution, the powder returned to the powder supply center is sieved through a powder sieve before entering the powder supply box. When changing colors, all powder pumps are lifted from the powder box and the powder box is removed from the vibration table. The cleaning process begins, and all powder pumps and suction pipes are lowered to the cleaning position, which is the blowing valve of the vibration platform. The powder on the inner wall of the powder road is automatically cleaned by compressed air. During this cleaning process, the inner walls of the powder suction pipe, powder pump, powder supply pipe, and spray gun are all cleaned. The outside of the powder pump can be cleaned with a manual blow gun. Seal the powder box, return it to the warehouse, and replace it with another color powder box. The remaining powder in the system is recycled into the waste powder hopper. The recovery pipe from the cyclone separator to the powder supply center is also cleaned with compressed air. After the cleaning process is completed, you can start spraying another color. It is recommended to send the recycled powder into the waste powder hopper within the first few minutes of the next color production, and not use it |

|||||

| Item Name | Item Details | Description | Quantity | Unit | |

| Electrical control system | Central control system of powder spraying room | Rack-Mounted Vertical PLC Central Control System for Spray Booth Powder Supply | Siemens rack-mounted centralized control system, friendly human-machine interface, using graphic symbols, easy to operate. The interface can display the operating status of the system such as the fan and spray gun, with multiple functions such as parameter setting, alarm information display, maintenance prompt, and cabinet door protection. It has functions such as control stability, forced stop of the lifter, programmable logic controller, flame detection alarm, control of the start and stop of the spray booth, control of the opening and closing of the main power supply, good anti-interference performance, and compliance with European CE industrial standards. | 1 | Set |

| Function: All components are brand-name electrical appliances, three-proof, and all circuit breakers are Siemens. The quality is stable. The electrical equipment and lines comply with the provisions of "Electrical Equipment in Spray Zones" and "Electrical Equipment in Explosion and Dust-Proof Zones" in GB15607-2008 4.8.1, and the electrical lines entering the spray booth comply with the provisions of GB50058. |

|||||

| Item Name | Description | Quantity | Unit | |||

| Powder room explosion-proof device system | A716/IR3 Point Type Flame Detector | This product has been upgraded to a 32-bit processor, combined with multiple algorithms specially developed for flame detection. While greatly improving the response speed, it also has high immunity to false alarms. It can be applied to indoor and outdoor applications with a large number of false alarm sources. | 1 | Set | ||

| Big Whirlwind Explosion proof System | Post-Filter Flameproof Valve | Installed between the large air inlet and the filter, 3 meters away from the filter frame. When the reverse pressure of the flameproof valve is greater than the set pressure, the flameproof valve closes. The flameproof technology can prevent the explosion from propagating to the front-end equipment, avoiding "secondary" explosion or burning. The principle is to use the pressure generated during the explosion to push the movable valve to block the explosion flame and pressure. The installation position is between the middle layer and the lower layer of the filter frame. | 1 | Set | ||

| Explosion proof filter system | Differential Pressure Detection Alarm Device | Installed between the upper layer and the lower layer of the filter frame. When the pressure exceeds the set range, the control system issues an alarm, prompting to replace the filter element, rotating vane, and air return valve device. | 1 | Set | ||

| Flameless Venting Device (Flameproof Venting Device) | The flameless venting device consists of a flameproof panel, a rupture disc, a flameproof connection line, and a fastener. The rupture disc is equipped with a signal device, which can be connected to the control cabinet or alarm through the flameproof connection line, and linked with the fan or other equipment. Brand: Huili, providing detection test reports and certification. | 1 | Set | |||

| Pneumatic Powder Return Valve | The pneumatic powder return valve collects ash from the ash 斗 and discharges it to the positive pressure return pipe. The working cycle of the pneumatic valve is determined according to the time. The interval between the pneumatic valve and the ash 斗,the air pressure of the ash 斗 and the pneumatic valve, and the air pressure of the pneumatic valve and the conveying pipeline are kept balanced. | 2 | Sets | |||