Flexible Independent Manipulator Robot

Independent manipulator:

Independent manipulator is suitable to match medium-sized power press.

This manipulator is driven by dual servo motors, and the arm suspension and the main bar are driven by servo motors to transfer workpieces between stations.

The distance between each arm is equal to the distance between stations.

The grabbing arm moves along the main bar X direction by one station spacing to move the workpiece from one station to the next, improving the degree of automation.

The aluminum profile of the suction arm has a strip groove, and the arm can be adjusted according to the size of the workpiece.

The material is grabbed with a vacuum suction cup; the tail is equipped with a safety frame; sound and light alarm devices and other related safety measures. Each arm of the manipulator is equipped with a sensor detection device.

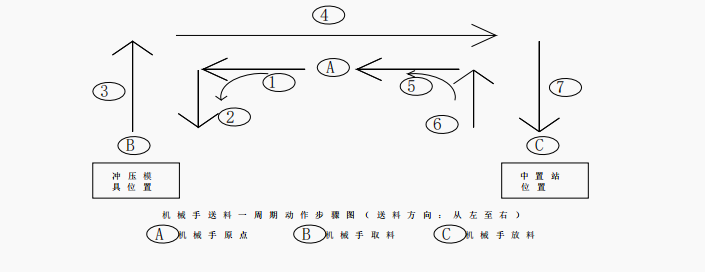

The grabbing arm moves left at the origin position A ~ descends to point B through ① and ② (the punch mold grabs the product) ~ rises through ③ and

④ moves right ~ ⑦ drops to place the product on the center station C ~ rises through ⑥ and moves left through ⑤ to return to the origin A. See the figure below for details.

Among them, ①~②, ⑥~⑤ can run arc curves through parameter setting to save time and improve processing rhythm.

| Transfer Direction | Left to right transfer (see schematic diagram for details) |

| Material Feed Line Height | To be determined |

| Operation Method | Color human - machine interface |

| X - axis Travel Before Operation | 2000mm |

| Z - axis Lifting Travel | 0~120mm |

| Operation Mode | Inching/Single/Automatic (wireless operator) |

| Repeat Positioning Accuracy | ±0.2mm |

| Signal Transmission Method | ETHERCAT network communication |

| Maximum Load per Suction Arm | 10Kgs |

| Transfer Sheet Size (mm) | Single Sheet Max: 900600 Min: 500500 |

| Workpiece Detection Method | Proximity sensor detection |

| Number of Suction Arms | 2 sets/unit |

| Suction Method | Vacuum suction |

| Operating Rhythm | Mechanical hand loading time approximately 7 - 11 pcs/min (specific values depend on the power press, mold matching, and SPM setting value of the power press, as well as manual riveting speed) |