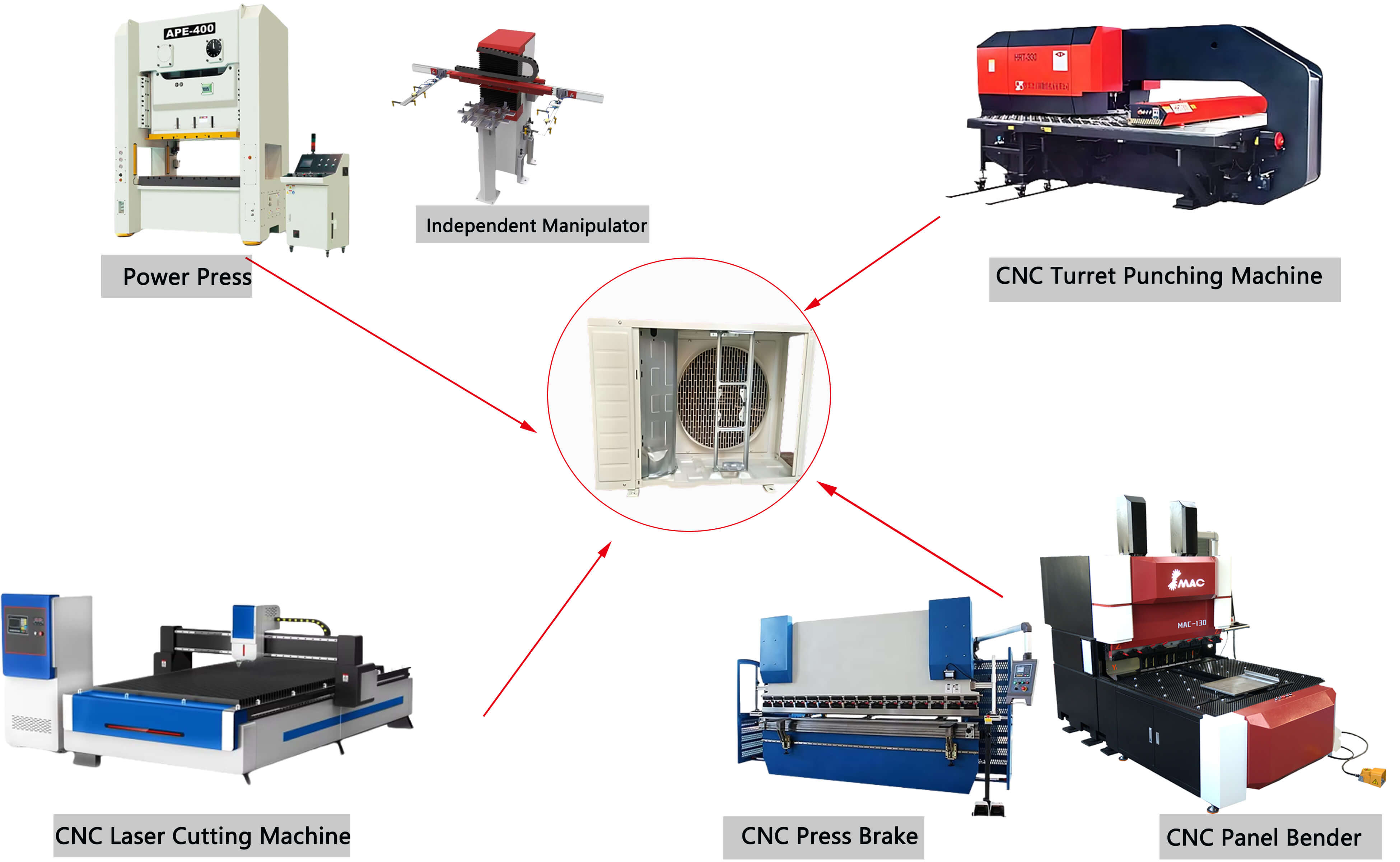

Sheet Metal Production Line for Air-Conditioners

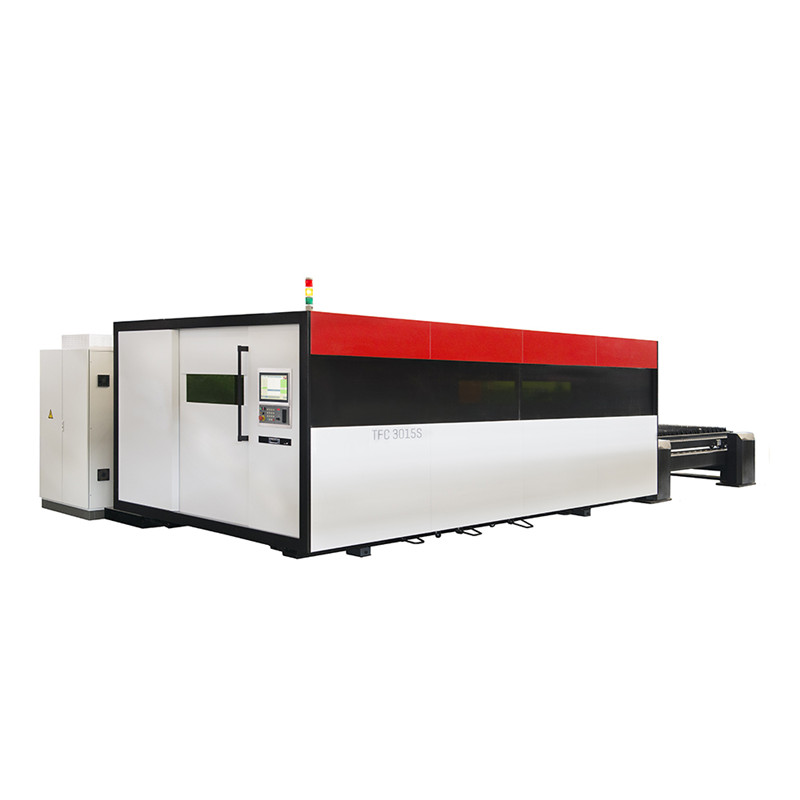

First, cold-rolled steel plates are sheared into blanks by CNC shearing Machine, which then undergo hole punching via CNC Turret Punching Machine or Power Press and hole processed by CNC Laser Cutting Machine. Next, CNC press brake and CNC panel bender are used to shape the materials, forming components such as outdoor unit casings and chassis. Subsequently, these components are assembled through welding/riveting/screw fastening and then subjected to electrostatic spraying and drying. Finally, accessories are installed, and the dimensions and coating are inspected for quality control, completing the production process. Throughout the entire process, structural precision and rust resistance are ensured.